How to Install a Double Sided Screen

In modern commercial displays, double-sided screen are widely used in shopping malls, store windows, and outdoor advertising due to their dual-sided display, space-saving design, and increased advertising exposure. Compared to single-sided displays, they allow brand messages to be transmitted simultaneously from two directions, delivering greater communication value.

As a professional digital signage manufacturer, Yetronic will provide detailed steps and key points on how to install a double-sided screen in this article, helping you understand the entire process from equipment selection to installation.

Why Choose a Double-Sided Screen

In digital signage applications, traditional single-sided screens can only display content in one direction, while double-sided screens can display advertisements or information in two directions simultaneously, improving communication efficiency and saving equipment costs. Taking Yetronic as an example, our double-sided screens can be used in various scenarios, including store windows, shopping aisles, outdoor advertising, and hanging installations.

Overview of Advantages

Brand and Customization Advantages: As a double-sided screen factory/OEM/ODM supplier, Yetronic offers customized design, size, brightness, operating system, and other services.

Pre-Installation Preparation

Pre-installation preparation for a double-sided screen is crucial to ensure safety, installation effectiveness, and subsequent operational stability. The following are the key preparatory steps:

Model Selection and Requirements Verification

5. Confirm customization services, prototype approval, delivery cycles, and after-sales support with the double-sided screens factory OEM/ODM supplier Yetronic.

Pre-Installation Site Preparation

5. Put safety isolation measures in place before installation to ensure worker safety.

Step-by-Step Installation of a Double-Sided Screen

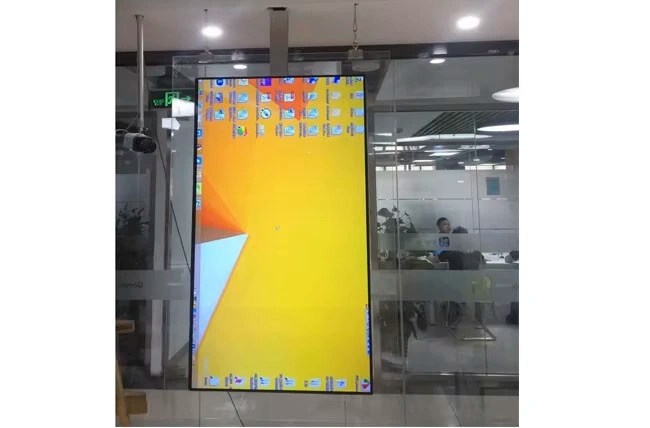

The following describes the installation process in detail, using a typical hanging installation scenario as an example. The screen is being installed as a Yetronic “hanging double-sided screen display.”

Step 1: Install the Hanging Rod/Bracket

3. Adjust the horizontal and vertical alignment to ensure the screen is not tilted after installation.

Step 2: Screen Installation

4. After securing, check that the device is stable and free of shaking.

Step 3: Initial Setup

4. Adjust display parameters such as brightness and contrast. If using a high-brightness double-sided screen for windows, you may also need to enable “Solar Mode” or “High Light Mode.”

Step 4: Testing and Acceptance

5. If using an indoor double-sided screen for shopping malls or an outdoor double-sided screen for advertising, also check the environmental compatibility (temperature difference between inside and outside, IP rating, etc.).

Step 5: Daily Maintenance Recommendations

4. For outdoor screens, pay attention to sealing, waterproofing, and lightning protection.

Installation Details for Different Application Scenarios

1. Store Windows — High-Brightness Double-Sided Screens for Windows

Store windows typically experience strong sunlight, requiring high outward brightness. A brightness of 700 cd/m² or higher is recommended.

During installation, ensure both indoor and outdoor electrical safety and cable protection.

2. Mall Aisles/Indoors — Indoor Double-Sided Screens for Malls

Malls, with their dense traffic flow, are typical applications for double-sided screens. Key considerations:

The mounting height, viewing angle, and sight distance should be designed appropriately to ensure effective dissemination of advertising content.

3. Outdoor Advertising – Double-Sided Screens for Advertising

The outdoor environment is more challenging, requiring protection from sun, rain, temperature fluctuations, and dust. Installation Notes:

Content updates should consider network stability and centralized control of multiple screens.

4. Hanging Method – Hanging Double-Sided Screen Display

The hanging installation method offers visual impact and high space utilization. Recommended installation method:

Regularly check the hanging rigging and bolt tightness.

5. Customized Production – Double-Sided Screen Factory OEM/ODM

As a double-sided screen factory/OEM/ODM supplier, Yetronic offers value-added services including:

Years of experience, stable production capacity, and factory-direct supply reduce intermediary costs.

These customized services help brands gain a differentiated competitive advantage in the UK and European markets.

Yetronic’s Advantages in Double-Sided Screen Installation

As a factory-based brand specializing in digital signage, Yetronic offers the following advantages in double-sided screens:

Global Service Network: For the UK and European markets, Yetronic provides CE certification, European power supply specifications, and logistics support to ensure a smooth project implementation.

Frequently Asked Questions (Q&A)

Q1: Is installing a double-sided screen more complicated than installing a standard single-sided screen?

A: Slightly different. While the steps are similar to single-sided screens (mounting, power supply, data, and debugging), double-sided screens require more stringent considerations regarding dual display, thickness, viewing angle, cable concealment, and structural support. Especially for hanging double-sided screen displays, higher standards for safety are required.

Q2: How should I choose brightness?

A: It depends on the environment. For store windows and direct sunlight, a high-brightness double-sided screen for windows (700 cd/m² or higher) is recommended. For indoor use in shopping malls, a model with slightly lower brightness but better color rendering can be selected. For outdoor use, a model with a higher IP rating and higher brightness is recommended.

Q3: After a double-sided screen is installed, can the content be displayed separately on each side?

A: Yes. Many double-sided screen products support displaying different content on each side.

Q4: What are the benefits of choosing OEM/ODM for a double-sided screen?

A: Through OEM/ODM customization, customers can obtain products that better suit their brands and scenarios. These options include specialized sizes, ultra-thin thicknesses, specialized brightness levels, customized protection, customized appearance, and customized software. These can enhance the end-user experience and brand differentiation.

Conclusion

If you’re considering how to install a double-sided screen, the selection, preparation, installation process, and maintenance recommendations described in this article, combined with Yetronic’s customization and factory advantages, will hopefully provide clear guidance for your project in the UK or European market.

Whether you require a double-sided screen or are looking for OEM/ODM support from a double-sided screen factory, Yetronic is your trusted partner.

We welcome your further consultation, prototype testing, or project evaluation.

Yetronic display